So she's been handed off to her new owners.

This website will remain for future reference. Many thanks for all your positive feedback.

Questions or comments? Contact Dave.

Many thanks again to all those who helped us with our boat research. This evaluation is here for two reasons: 1. Because we initially found it very difficult to locate information or owners of Cabo Rico 34s to answer our questions. 2. To give something back for all the generous help we received from others in choosing the right boat. This is for anyone who may be interested in our research, evaluation, comments, and the comments of many others. Much of the info here is a compilation of responses to inquiries, both ours and others' since we began research and eventually acquired Cigano in early 2006. It's the best way we've found to answer most of the questions we get.

The specifics in these web pages are correct and accurate to the best of our knowledge. Portions have been corroborated with Cabo Rico, various publications, brochures, etc. The stated opinions are ours with influence from others. Both positive and negative comments are included. Revisions will be made as new conclusions are drawn or new information becomes available. There are so many great features designed in that it's hard to mention them all. Here is a link to the Cabo Rico owners group forum. Anyone interested is welcome to join.

General Comments:

Cabo Rico has been building boats since 1965. By locating in Costa Rica, they are reputedly able to deliver more quality than comparable US built boats for the same price. It is claimed that they spend more time laying up the hull and deck than most builders spend on their entire completed boat. - About Cabo Rico. Here's a review of the CR34 by Sailing Breezes Magazine.

Cigano was completed in 1990 in Costa Rica by Cabo Rico Custom Yachts and designed by W.I.B. Crealock who died in 2009. Cigano specs.

Cigano has a cutter rig as do most Cabo Ricos - sail options are many when you consider all the reef points on the main and staysails and a roller furling headsail. Although various numbers are bandied about, we believe Cigano weighs around 16,000 pounds when empty.

When fully loaded with provisions, tools, spares and with full tanks she sits slightly bow down and lists slightly to port - the largest water tank is port-side under the forward berth and we have hundreds of pounds of ground tackle on and in the bow. The new Cabo Rico 34/36 has an extra two feet on the stern adding about a thousand pounds to its weight. The interior has not changed, only more locker space on the expanded back porch, for a huge increase in cost.

Cigano has had extensive upgrades recently including new standing rig, lifelines, canvas, engine, headsail and furling/reefing system, Monitor wind vane, batteries, electrical wiring, and much more. We decided to break our budget and pay extra because she was ready to sail away as-is. The only work needed was restitch the UV cover onto the furling headsail due to thread decay from UV solar rays. The hull and deck are insulated which keeps the cabin quiet and much cooler than expected. Ventilation is excellent. After being closed up, the interior cools off quickly upon opening some ports and hatches.

So far the longest stint we've spent onboard has been about 3 months, moving nearly every day. Living aboard for that duration was easy and comfortable, considering of course that it is a boat. At the end of that session, we both felt we could have easily spent another couple of months onboard.

Since acquiring Cigano we have found many pleasant Cabo Rico surprises, including in particular, a complete set of blueprints they provided, inside a sealed PVC tube, that include electrical, mechanical, plumbing, layout, and elevation drawings.

The hull and deck are nearly bullet proof, very solid both in construction and connection. Sometimes it’s reported that Cabo Rico's hull is balsa cored, however a layer of balsa is actually added to what is essentially a completed solid fiberglass hull, and then covered with a thin fiberglass skin. The balsa is not a structural part of the hull, but for thermal and sound insulation. Fiberglass floors stiffen the hull and support a fiberglass subfloor—there is no wood to rot in the bilge. The teak-and-holly sole is laid over the subfloor and epoxied, making it very solid. The lead ballast is internal and lowered into the keel cavity in several sections, then glassed in place fo form a waterproof enclosure.

A structural bridge supports the foot of the mast level with cabin sole, keeping the mast out of bilge water. The bridge is built of heavy fiberglass with an aluminum plate fastened on top. The aluminum mast step can be a dirt catcher - some teak inserts could improve its appearance. Occasional clearing of the drain holes should be done. The space below houses the 35 gal holding tank.

Cigano has a well-fortified fiberglass keel. The rudder hangs on the back of the keel. Rudder stock is inch-and-a-half diameter solid stainless steel with a stainless steel rudder shoe. The top of the fuel tank, which is encased in the mid-portion of the keel, as well as the engine bed, stay dry because there is a very deep bilge section aft with pump intakes/strainers where all water flows that enters. All floor stringers and framework are solid fiberglass.

On deck, the raised U-shaped bulwarks add tremendously to the rigidity, strength, and safety of the boat and enable the vertically attached lifeline stanchion bases. Side decks are wide, with plenty of hand-holds and the double lifelines (also replaced in 06) are almost hip high aided by the high bulwarks. Cigano is equipped with mast pulpits, which we considered removing for vanity. But once we used them in rough seas, we are more tolerant of their appearance - we love the ability to use both hands while standing at the mast. They also are handy for fastening idle halyards for easy waste-level access, which also holds them away from the mast preventing halyard-slap. Moving fore and aft is easy except the mast pulpits create a bit of a zigzag passage between them and the two forward shrouds. There are two deck scuppers on each side. The teak caprail requires maintenance but is very solid and beautiful. Two sets of 3 large (fore, aft and midship) cleats each have their own very heavy cast aluminum chocks, which are tightly fit/cut into the bulwarks. An ABI manual windlass handles anchor chain and line. Many prefer an electric, but the manual windlass is 100% fool proof, and eliminates the need to run the engine to charge the battery after hauling up the anchor. We use the windlass for breaking the anchor out of the bottom then haul it up by hand. The stainless steel bowsprit capped with teak is rock solid with two whisker stays and a bobstay, and there are two anchor rollers. Two deck pipes feed the divided chain/rode locker. There is also an overboard-draining foredeck locker with dual teak open-grate doors with enough room for a couple of fenders, lots of lines, our disassembled Fortress FX37 anchor, and more. Other deck hardware is top-notch. I believe Cabo Rico started using vinylester resins in 1988 or 89 and I think all 34s were built since then, so blister worries are negligible. The stainless steel-capped, heavy duty, molded in rub strake is another nice feature.

There is a small back porch behind the cockpit, but inside the bulwarks. It's great for stowing sandy shoes and small gear such as boat hook, fenders, dock lines, etc. This area also houses two separate propane tank lockers with overboard scuppers. There is enough room on the back porch to stand behind the bimini when cooking on the stern-rail mounted grill. We particularly like our discovery that stowing three fenders in a stack on the back porch, behind the helm seat, makes for easy and handy storage, as well as creating an excellent backrest.

Rig:

The standing rig is outboard so there are no through-deck chainplates* (see below).

Our stainless steel rigging was replaced in 2006 and Norseman mechanical terminals were installed as well as a Profurl headsail reefing/furling system. Mechanical fittings are preferred over swaged for strength and ease of repair. Running backstays for the staysail are provided and in our opinion, are only necessary when wind gets above 25-30 knots. We have a mast-mounted radar above the spreaders. The insulated backstay doubles as an SSB antenna.

Running rigging is all rope and internal in mast and booms. There are mast-mounted self-tailing winches for mainsail, genoa, and staysail, and also a shared winch for mainsail outhaul and reefing lines. The mid-boom mainsail sheeting bears a lot of pressure. and the main sheet winch handle cannot take a full turn under the dodger. Blocks need to be clean to minimize friction. Main sheet traveler is plunger/pin-anchored without the aid of line-controls. The boom will chafe on the bimini top if there is no wind whatsoever to fill the sail and lift it, light topping lift pressure is preferred under those conditions. We have a full-battened main and staysail with three mainsail reef points and internal reefing lines. The full battens enable the lazy jacks to perform their job well. The staysail boom swings at knee level and could cause pain if you're not attentive. There are two reef points there. The stemhead fitting for the furling headsail is at the tip of the bowsprit. It all adds up to many sail area options. A whisker pole and/or an asymmetrical spinnaker - both on our upgrade list - will be a big help off the wind.

*A note regarding chainplates. While building the very early 34s, Cabo Rico had a supplier sell them a mixture of material (304 and 316L stainless) for the chain plates and bow sprit. As a result there were problems that arose with some of the chainplates but not all of them. We are aware of one 34 (hull #2 I think) that was dismasted due to this problem. Cabo Rico took care of the problems to the owner's satisfaction as far as we know. I inquired about this and Cabo Rico suggested that - paraphrased from their response: (One might want to find a local lab that can analyze the material to see which it is. Unfortunately, the bow rail is welded to the collar on the bow sprit and it is very difficult to change this fitting. You will want to talk to a local welder to find the best method for changing this out, if necessary.) . . . (Unfortunately there is no dependable record of which boats received the improperly formulated stainless for their chainplates. Also, there is no guarantee that the lab analyst's findings from one chainplate would also extrapolate to the others. Also, if the chainplates are found to be constructed of the correct stainless steel formula, that would not necessarily mean that the bow sprit collar was part of the same batch either. The round stock and flat stock might be the same BUT they might be different.) Our former owner took several of our chainplates to a metallurgical lab, and they were cleared.

Cockpit:

The cockpit is roomy, the teak seats are comfortable, and the slope of the coaming is good, nevertheless we still use small movable cushions which we store in the lazarette. A benefit we have found with the unvarnished teak is that black flies hate it and won't stay on it if it's wet. If we sail through a fly swarm and they become annoying, we just toss water on the seats, nearly eliminating the flies. The layout is good with clear easy access to headsail sheet winches and no obstructions to hamper winch-handle cranking. There are line storage bins on either side under the winches. The pressurized cockpit-shower on the port side connected to the hot/cold water system is an often used, great feature. Storage space is fair to good. There are two lazarettes. Port side we store 6 or 7 medium sized tool/spare part cases, over half a dozen life jackets, the companionway drop-boards, several hundred feet of line, dock lines, and other miscellaneous gear. The lazarette floor and sides are removable to access wiring, piping, supplemental batteries, electric bilge pump, etc. Also mounted in the lazarette are the linear drive and central computer for the auto pilot, the fresh water filter housing, and the Xantrex 110 volt battery charging system. Our easily removed helm seat is concave with a sealed closed-cell foam cushion - very comfy. With the helm seat in place, the aft lazarette can be opened a few inches but full access requires removal of the seat which can be stowed on the back porch. This lazarette is shallower but still houses half a dozen tool boxes, several hundred feet of line and electrical cords, the emergency tiller, water buckets, and a whole bunch of other gear. The removable lazarette floor gives access to the steering system and other components.

Because the helm is well balanced the wheel is small and unobtrusive. The cockpit is very comfortable for about seven adults and two more can use the stern-rail seats. More could be seated in the cockpit if desired. Visibility from the helm is good. The bimini with zip-in connector to the dodger gives us shelter from rain and sun. It doesn't keep the cockpit completely dry when raining, but it helps to make cockpit life more tolerable. A pair of small zip-in inserts between the forward section of the coaming and the bimini would prevent rain dripping on the forward section of the cockpit seats. Our snap-on sun covers for all the windows in dodger, zip-in, and bimini really extend their life. There is a 17" high companionway bridge deck to help make the boat ocean worthy. The two teak seats mounted on the corners of the stern rail get more use than we expected. We made an insect screen that can be dropped over the dodger and bimini which completely protects the entire cockpit.

Engine:

A Yanmar 3 cylinder 27 horsepower diesel was installed new in 2001 due to damage caused by marina staff. We initially thought the boat may be underpowered with 27 hp. But in 99+% of conditions it's sufficient, and it is a fuel miser, burning less than half a gallon/hour at 5.5–6.0 knots. The only situation we've wished for a bit more horsepower is when motoring directly into very steep, large seas. Cigano sometimes looses momentum and has to work back up to speed between waves, in which case we just fall off a few degrees, haul up a small amount of sail, then motor-sail. This immediately solves the problem, greatly improves comfort, and notably reduces the required engine RPMs. In lieu of the 16x12 3-blade fixed prop, we might consider a Max-Prop or similar to add pitch control and for easier backing.

The engine is under the galley and settee, so the 1-1/4" prop shaft is fairly long, running through a pillow block bearing below the companionway sole. We have a PSS dripless stuffing box. Because there probably is no other way to do it, the raw water, raised anti-siphon loop valve is run up inside the galley trash compartment above the engine. The valve's water vents overboard at the port hullside sheer.

Access to the engine is very good from the front and starboard side thanks to a removable hinged cover which is the base of the settee. Rear access is a bit more limited, but so far I have not found anything that can't be reached. Access there is through a hinged door on the aft side of the galley that opens to the engine's aft upper section. There is a floor panel that gives you access to the back of the transmission and a third access door on the side of the removable settee base lets you view the engine's starboard side, maybe check oil, but that's about all. There is plenty of space under the engine. Our fuel filter housing is hung on the hinged aft access door so access to change the filter is easy.

We have a retrofit 90 amp Balmar alternator which fits tightly in the space. The closed cooling system heats the water in a Seaward 6 gal. water heater under the dinette settee.

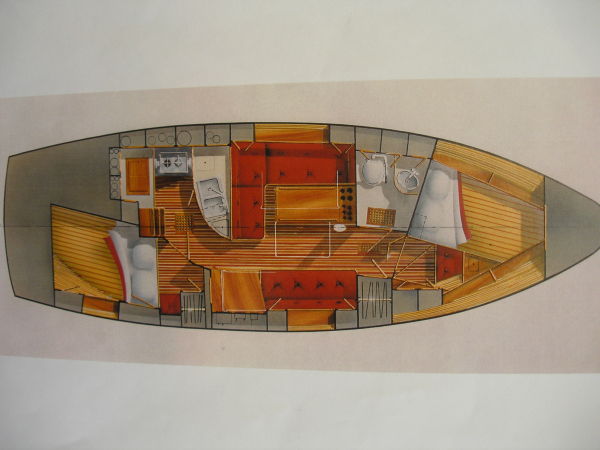

Cabin accommodations:

We have a custom-made heavy duty bifold companionway door with tinted glass that makes access to the cabin quick and easy. We use it in lieu of the drop boards whenever we are aboard. We also made a matching screen door. The companionway steps are angled up on the sides to help keep your feet in place when the boat is heeled. Solid hand-holds are to starboard & port. On the port side of the stairway is a switch for the low-level cabin courtesy lights.

Walking below, the first thing you notice is the generous amount of beautiful teak. The wood is the golden honey colored teak of Costa Rica. The cabinetry and construction are hand-crafted and spectacular. We love the look and feel of the cabin and quality is evident everywhere. Besides plenty of designed hand-holds, there are also galley fiddles, door frames, and other things to grab hold of, all heavily designed to support a human’s weight in a seaway. The cabin sole below the companionway stairs houses a dust-catcher bin under a teak grate incorporated into the hinged access panel for the bilge, drive shaft and transmission.

The U-shaped galley is directly ahead of the stairs and to port. We have a gimbaled Tasco two-burner propane stove/oven which accommodates us well. The stove is very miserly on gas. We also cook a lot on the grill outside when it's warm. The galley is laid out well but suffers from a shortage of open counter space as does virtually every boat this size. There is a teak tray over the stove and beautiful teak covers for both stainless steel sinks that add to the counter space as deployed. There is hot and cold pressure water and a backup fresh water (cold only) hand pump.

We have a six cubic foot 12 volt DC Adler-Barbour Cold Machine refrigerator/freezer. It is top-loading with well insulated double doors and it will make ice! With the refrigerator operating we needed to run the engine about an hour a day to keep the batteries charged. But now, since installing two solar panels we can go almost indefinately unless it's heavily cloudy for days. We do still run the engine to heat up the 8 gallon water heater.

There is a cavernous storage bin under the forward port corner of the galley counter. We store loads of beverages, paper towels, pots and pans, etc. there and most of the time it is filled only halfway. It requires a long arm to reach the bottom. The galley sinks don't drain as quickly when the boat is heeled or listing to port because under those conditions, the sink bottom is near the waterline. There is a teak covered trash bin to starboard of the sinks. The above-counter cabinets are enclosed by sliding doors and space is adequate but not remarkable. The addition of a storage hammock for food above the galley is essential to take up the slack, and it functions very well in any sea conditions. There are two small drawers below the sinks that work for tableware and other essentials. For galley ventilation there is a fan aiming at the cook, an overhead screened hatch, 2 screened opening ports above the stove and one more facing the cockpit. Bottom of the stairs to starboard is the enclosed aft cabin with a vented and lighted hanging locker and several other small vented lockers. We alternate its use between tons of storage and as a guest cabin. Most of our guests say that there is adequate room for two although vertical space above your knees is limited due to the cockpit well. The berth is over 7 feet long on one side and works well as a sea berth convenient to the cockpit. There is a padded seat back that uses the mattress as a seat. The cabin will hold a lot of gear if you choose to use it for storage but the access panel to the stuffing box/shaft seal and the deep bilge are below the aft portion of the berth so you would need to remove your stored gear in order to gain access there. The aft cushion is split to enable easy access into the bilge opening. Ventilation is good with screened opening ports facing the cockpit and outboard, a screened overhead hatch and a louvered door. A fan compliments the ventilation and there are plenty of lighting options.

Forward of the aft cabin, the bulkhead supports an aft facing navigation table and the main electrical panel. The nav table top is hinged to access a large nav-gear storage bin. The main electrical panel hinges forward and down to access AC and DC power wiring. A second outboard panel contains engine and charging monitors, a VHF, and several other components.

The aft end of the starboard settee doubles as the nav table seat. A single berth is set up by pulling a short extension aft from under the settee. Your feet end up under the nav table with limited, but adequate vertical space.

Forward of the galley to port, an L-shaped settee wraps around the dinette table. The dinette settee pulls out to make double berth to port. A heavy duty teak table hinges up to stow against the forward bulkhead, and behind the stowed table is plate and glass storage and a silverware drawer, a great use of the space. The table rests on a single leg when down and can open to serve the starboard settee as well, providing seating for 6 and more. Under and above/behind the settees are vented lockers, cubbies, and bookshelves. The main cabin has another large overhead screened hatch, 4 more opening screened ports, and two more fans. Overhead lights and reading lights abound.

The head, vanity and shower are forward to port with a shower sump with electric overboard pump, Wilcox-Crittendon Skipper II manual toilet, and vanity. The sink faucet is on a retracting stainless steel reinforced hose and doubles as the shower head. Ventilation consists of a screened overhead hatch, a screened opening port, a fan and a louvered door. Storage is a bulkhead mounted medicine cabinet, three above counter louvered lockers, and a louvered cabinet in the vanity base. Across from the head is another lighted and vented hanging locker (the largest onboard) with two overhead shelves. Cigano's prior owner had a central air conditioner installed in the locker, not necesary on Lake Superior; we removed it and are happy to have the storage space back.

The enclosed forward cabin has an offset double berth to port and a seat on the starboard side. The berth is comfortable for two — I am six feet tall. Janet is quite claustrophobic but has no problem in the forward cabin if she sleeps on the outside. She's tried out the aft cabin as well with no problems. Shelves on each side and vented lockers to starboard top off the storage with more reading lights and an overhead light. A nice feature is the forward facing screened opening port (don't open it after a rain) as well as another one to starboard and the screened overhead hatch. Forward are the access doors to the anchor chain locker.

Shore power-fed 110 volt outlets are scattered in the main cabin, aft and forward cabins and head.

Overall ventilation is excellent - 11 screened opening ports and 5 screened hatches. I built a hinged screen door for the companionway as well.

Leaks are negligible: an old gasket needed to be replaced on one port, of course a bit of rain blows into the mast top, drains into the step, then into the bilge, but aside from that no water gets below. We have overpowered Cigano several times, burying the rail and getting the boat good and wet and we've close hauled into about 7-9 foot seas. We've also buried the bow both in standing waves and very large seas. No water inside at all, and the bilge was as dry as when we started.

Interior hardware is mostly ABI and is pretty good quality.

Electrical, plumbing, tankage:

Access to mechanical and electrical systems is what you'd expect - a mix of good, fair and poor. You need to be a contortionist to get at some of the plumbing. Cabo Rico's complete set of blueprints has been a big help in getting us oriented. There are five batteries, 3-G27s and 2 G24s, sealed gel-cell deep cycle. The engine start battery is under the companionway step. Four house batteries include two under the companionway step and two in the port cockpit lazarette. Our Xantrex True Charge 40 amp charger has worked great. As mentioned above, we have two solar panels for supplemental charging. They run through a Victron MPPT inverter/charge controler and they turned out to be a huge benefit; money well spent.

WIRING: The boats AC and DC wiring converge inside the hollow wall between the aft cabin bulkhead and the nav station. The hinged control panel reveals a large terminal block against the back wall with a clear plastic cover over the separated AC and DC connections. The control panel - made by Paneltronics - is well designed but after 16 years it has a few backlights burned out that illuminate the labels; some LEDs are on the to-get list. There is also a removable teak wiring-access panel at the base of the wall inside the aft cabin. The original wiring is well organized and fed through fiberglass conduits glassed onto the hull and some additional wiring has been added.

LIGHTING: There are adequate options for lighting the cabin including about 8 reading lamps, 6 overhead lamps and a set of low level courtesy lights throughout the cabin. The nav table has a florescent overhead and a flexible chart light. A florescent fixture is mounted under the deck above the forward section of the galley countertop. Both hanging lockers as well as the engine room also have their own built in overhead lights.

Navigation lights include both a tricolor masthead light for sailing and red and green bow and white stern lights for motoring. There are spreader lights and a combination steaming/deck light as well. Switched power is provided for cockpit instruments and lights.

AC ELECTRICAL: There are five 110 volt AC outlets, one in each cabin and head and two in the main cabin - they operate with shore power only, no built-in inverter although we have a small portable inverter for recharging small appliance batteries, etc.

There is a bow-to-stern grounding system using heavy wire, copper strips, attached to a reasonably sized scintered bronze ground-plate.

FUEL: The 40 gallon fuel tank is integral in the keel. There is a cleanout/access panel and a dipstick to back up the fuel gauge. We have not yet opened the access panel. The fuel tank is large enough for Great Lakes use. For remote cruising areas we carry an extra fuel can on the back porch but have not needed it. Cigano has a Racor #500 separator/filter system and a primary filter. We considered installing a fuel washing system, but have never had fuel problems to convince us we need it. Fuel gauge and suction-pressure gauge are on the outboard-side panel at the nav station.

HOLDING TANK: The 35 gal holding tank is centerline in the bilge above the keel near the base of the mast. Pumpout is via a deck fitting, or an overboard hand pump (which we cannot use on the Great Lakes). Plumbing to and from the holding tank snakes around a bit, but it's doubtful that one could improve on the system. There is an access panel on top of the holding tank I hope we never have to open.

FRESH WATER: There are 2 fresh water tanks totaling an estimated 140 gallons (we have seen claims of between 135 and 165) - the largest one is port-side under the forward berth and another starboard-side under the aft berth. The diverter valve controlling flow from the two tanks is beneath the companionway stairs under the cabin sole access panel. The hot water plumbing runs under the dinette settee into the engine/shore power-heated water heater then to the various outlets. Fresh water plumbing consists of fiber reinforced plastic hoses. Water flow to the sinks/showers is adequate, supplied by a Jabsco sealed pump with accumulator tank and in-line filter cartridge in the port cockpit lazarette. There is a backup galley hand pump. We may add a diverter valve to enable seawater to be run through the hand pump as a water conservation measure. We have not tried it but it appears that starboard scuppers could be closed and the deck filler-cap opened to enable rain water collection into the aft fresh water tank.

PUMPS: The head's shower flows into a sump drained overboard by an electric hand-switched pump.

Bilge pump intakes are in the deep bilge under the aft cabin berth. The berth cushion is split to allow easy access and there is a large access panel, but the bilge is very deep and narrow enough to make reaching the bottom difficult.

PROPANE: Gas for stove/oven feeds from the port-side dedicated propane locker (spare tank in the starboard locker) and is controlled by an electronic solenoid. The solenoid cutoff switch with indicator light is sensibly placed on the outboard power panel at the nav station, visible from the galley and everywhere in the main cabin.

Underway:

With engine in forward, the force is with us and we are one with the force. In reverse, the dark side can decend upon us. Backing out of a slip is typically difficult for any boat with a full keel, even with a cutaway, and Cigano is no exception. She prop-walks to port and we use this to our advantage frequently. She will back directly into the wind. We have been able to hold her in position with the stern to windward while feathering the engine; we haven't had to depend on this to work in a serious emergency, but we believe we could do it.

Docking in very strong crosswinds requires a single precise turn the first try. If the wind is blowing across the beam and you have to stop or slow significantly to realign the boat to the slip, the cutaway forefoot will allow the bow to be blown off and you'll most likely have to bail out and start over. But when it's calm we look like experts - we can park the boat on a dime using the prop-walk to turn the boat in just slightly over its length. For docking we installed a movable cleat on the genoa track that we locate just forward of the helm. With a single dock-line on that cleat we can pull into the slip, secure the line to the outer cleat on the dock or drop it over the cleat and run it back to the headsail sheet winch. Once secured in this fashion, with the the transmission in forward and the engine idling, or for strong crosswinds, 800-900 RPM, the boat nestles comfortably against the dock. We can then take all the time we want to step off, set the bow, springs, and stern lines. This allows for single-handed docking . . . pull up close to the dock, stop forward motion at the tie-up-point, shift into forward, jump off, cleat the line, and stand and watch as Cigano snugs beautifully up against her fenders. Done properly one looks like a master mariner. I don't think about potential failures because they have not yet happened.

The substantial encapsulated ballast keel has a flat bottom. Grounding damage is low on the worry list, except of course, the long flat bottom becomes a negative when it comes to getting loose again. As expected of all sailors, we have plenty of experience with thankfully gentle groundings in soft materials.

When motoring, the autopilot holds course with ease. For hoisting or lowering sails, our new Tides Marine SailTrack is amazing. We can raise and lower the sail with ease. It drops like a rock into the lazy jacks.

With all its weight Cigano powers up a bit slowly, but once moving the weight helps keep it that way. In flat seas we can tack through 90 degrees apparent and she points 35-40 degrees apparent. As seas increase we fall off 5-10 degrees in order to keep driving. Even with the low freeboard, it takes a whole lot of wind to bury the lee rail. She's a pretty stiff boat, so if we manage to put the rail into the water repeatedly or persistently, it is clearly time to reduce sail, at which point she sails better and faster. In general, motion is easy and smooth and the cockpit is dry and comfortable. It takes some very large square waves to bury the bow far enough to even get any spray into the cockpit. Work on deck is fairly easy with plenty of space, hand-holds, and a feeling of safety. Off the wind she tracks very well, especially when compared to our old fin keeler, and the auto-pilot does not work too hard. The helm is well balanced on all points of sail. Our Monitor wind vane steers admirably on all points including downwind, where as one would expect, it requires a stronger breeze than with a reach. There is a heavy duty emergency tiller in the stern locker. It is easy to find and deploy but the stern locker must be open to access the rudder post. Under truly extreme heavy weather with boarding seas, flooding would be a concern.

We have not tried it underway but it appears that the tiller would be easy to connect and steer. Although Cigano has a fairly fine entry for a beam of eleven feet, the clipper bow design makes it very buoyant underway and helps keep the boat dry, but this buoyancy can slow us down when motoring directly into heavy seas. Again, if we fall off a few degrees and motor-sail, she charges along much more easily. And if you manage to hold the rail underwater, you are way overdue for reducing sail which at that point will notably improve both performance and comfort.

A full keel offers arguably a better ability to hold the boat on course while underway, but certainly poorer maneuverability in close quarters. We rationalize that maneuverability in harbor is overrated - docking in cross-winds is just something that must be learned. And we maintain it's good for ones character to be the harbor entertainment on occasion while docking - keeps you humble.

Regarding anchoring, we are very happy with the Bruce 44 pound anchor. It is attached to 100 feet of 3/8" chain and 250 feet of nylon rode. We typically let out an amount of chain for about 3/1 to 5/1 scope in normal conditions, 7/1 in strong winds, tie on a bridle, then drop an extra few feet of chain through the roller and tie it off to one of the bowsprit sidestays. This prevents the chain from contacting bobstay, which makes noise. The Bruce sets on the first try 98% of the time and rarely drags once set. We've experienced a 360 degree spin over a mud bottom with winds well over 40 knots, and in sand, a 270 degree wind shift with thunderstorm squalls all night long pushing us toward a lee shore. But, although we "trust" the Bruce, we still post an anchor watch through nights like those. We have not yet tried the big Fortress FX37 but I believe once set in sand, it may hold through a hurricane. We also have a backup 22 pound Delta plough but have never deployed it. Because it is geared so low, the heavy-duty manual windlass is only for breaking the anchor loose from the bottom. We don't mind the exercise of handing the chain aboard. The action of the windlass handle comes close to the staysail and will hit the canvas cover if the sail is stored off center to starboard.

Conclusion:

As we expected, we're very pleased with the quality, construction, sailing characteristics, accommodations, and nearly everything else about Cigano. Cabo Rico has put much forethought and care into every detail of the design and building of this boat. She is seaworthy and built to last. Stepping onboard, you immediately get a sense of quality which follows through everywhere, above and below decks. When we look around our harbor and other harbors at all the fine sailboats, we wouldn't trade Cigano for any other boat.

It was clear from our first sea trial that underway, she's smooth and easy to handle shorthanded and can handle a reasonable load for long term cruising. We like the low freeboard for reduced windage, ease of boarding, and safety, but important also, it gives way to the beautiful traditional lines which are pleasing to view from any angle. If we often had larger groups for extended stays, we would consider a larger boat, but for the time being there is plenty of space for the two of us and our occasional guests. When the dock walkers are out, Cigano is one of the boats that gets a second look and often an inquiry. Even the toughest critics who come aboard have a difficult time finding anything wrong, aside from their own personal preferences.